COLD FORMED STEEL

Cold Formed Steel Tubes and Profiles Cold-formed steel sections are the name or term given to end products that has been rolled or pressed from sheet metal (or coils) into the desired shape. Steel sheets are deformed using rolling, stamping or pressing to deform the sheet or coil of steel to the end product.

The rolling, pressing or stamping of coldformed steel occurs at room temperature. End products include items such as structural tubing, lip channels, purlins, open channels as well as cold-formed open profiles and closed profiles.

When press-braking or cold-roll forming forms steel, there is a change in the mechanical properties of the material by virtue of the cold working of the metal. When a steel section is cold-formed from a flat sheet or strips the yield strength, and to a lesser extent the ultimate strength, is increased as a result of this cold working, particularly in the bends of the section. Cold-formed steel sections tend to be more sensitive to local buckling effects than typical hot rolled sections.

Cold formed steel sections and profiles are used in a variety of industries, which include the following:

Construction:

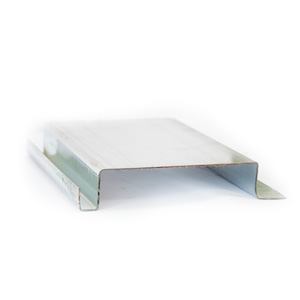

Lipped Channels, Zed Profiles, Top Hats, Structural Steel Tubes

Trailer Manufacturing:

Steel Tubes, Top Rail Open Profiles, Side Rail Open Profiles, Cross Members

Doors and Windows:

Shutter Door Guides, Steel Tubing

Agricultural:

Pressure Tested Steel Tubes, Z275 Pre-Galvanized Steel Tubes